Search This Blog

Gained exposure to Human Resource by working with establishments in India and abroad having multiple industries like Cement, Construction and M.D.f Board Industry. available with advice and help to new H.R fraternity to handle "Personnel / Auditing" functions of their establishments.

Featured

- Get link

- X

- Other Apps

TPM - 8 PLANT LOSSES

Total

Productive Maintenance

Total

Productive Maintenance (TPM) is a system of maintaining and improving the

integrity of production, safety and quality systems through the machines,

equipment, processes, and employees that add business value to an organization.

One of the

major goals of TPM and OEE programs is to reduce and/or eliminate

what are called the Eight Big Losses – the most common causes of

equipment-based productivity loss in manufacturing. ... Capture the Eight

Big Losses to gain additional actionable insight to the OEE Factors

of Availability, Performance, and Quality.

OEE (Overall Equipment

effectiveness) is the main performance measure that drives action within Total

Productive Maintenance (TPM) and is used by the teams to focus their

continuous improvement activities as well as identifying those areas that

require resource. The preferred OEE calculation is based on the

three OEE Factors: Availability, Performance, and

Quality. OEE is calculated by multiplying the

three OEE factors: Availability, Performance, and Quality.

Plant managers, line supervisors, and machine operators work with the

equipment day in and day out, and they know what's normal and what's not.

A TPM approach

gives operators the primary responsibility for taking care of their equipment, including cleaning,

inspection, and basic maintenance.

These basic seven pillars of TPM:

·

Autonomous maintenance.

·

Kobetsu Kaizen (Focused Improvement)

·

Planned Maintenance.

·

Quality maintenance.

·

Training

and Education.

·

Office

TPM.

·

Safety

Health Environment (SHE)

Dheeraj Chaubey

dheerajchaubey.blogspot.com

+91-7873268773

HR Professional

- Get link

- X

- Other Apps

Popular Posts

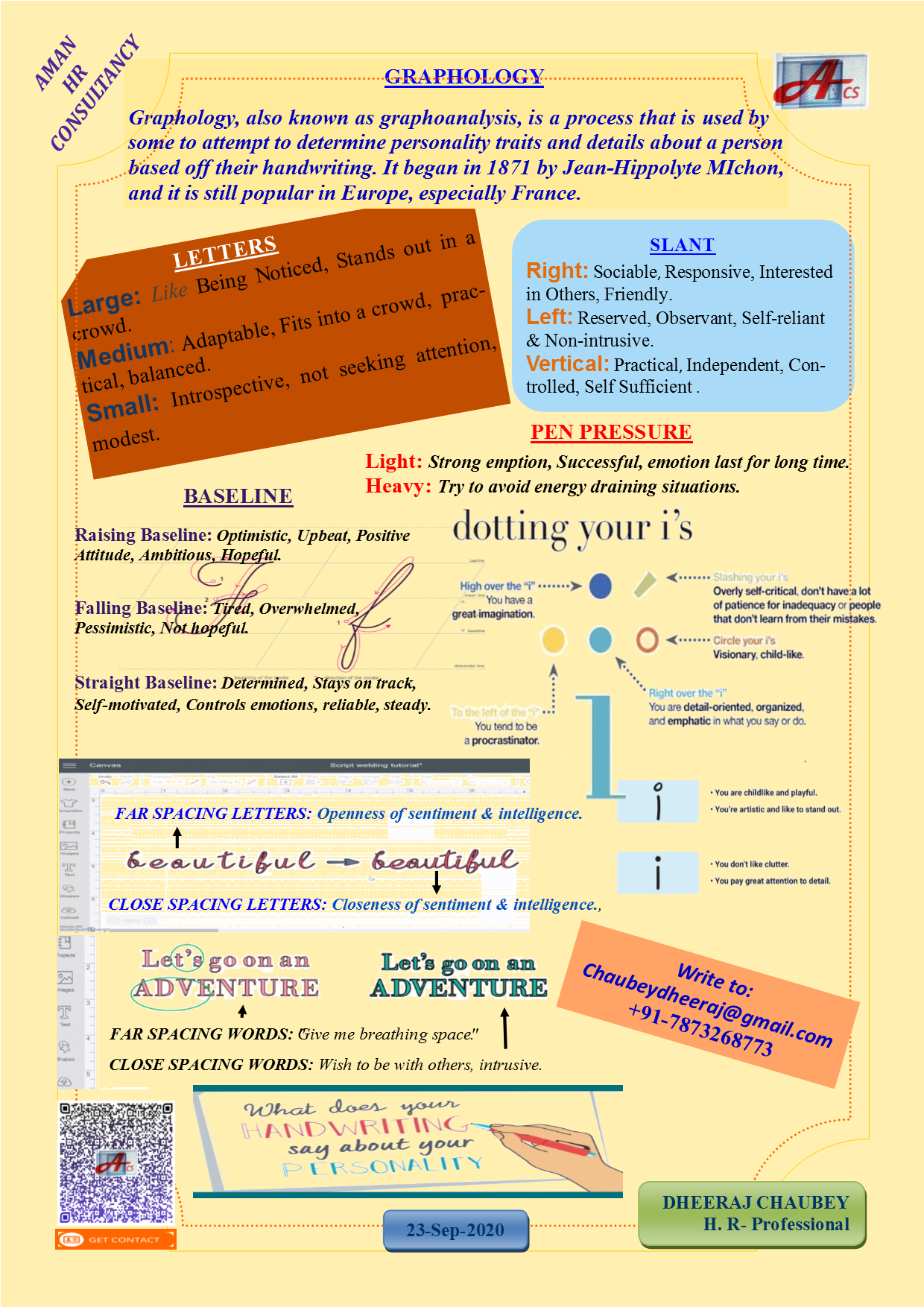

Human Resource Management Called "GRAPHOLOGY" an effective tool of Human Resource Management".

- Get link

- X

- Other Apps

Comments

Post a Comment